General Contractor / Field Construction

ICT Industrial is an industrial construction contractor providing project management, multi-discipline craft labor, procurement, subcontractor management, and engineering services. Our management and project personnel have incorporated decades of experience combined with its methodology to provide improved project value to its clients.

ICT Industrial offers services throughout North America in a wide range of sectors such as energy, chemical, mining, manufacturing, oil & gas, and water treatment.

By minimizing the need for single-discipline focused contractors, ICT Industrial benefits our Clients by remove both compounding markups/margins, while also reducing overall project risks associated with the management of additional interface points.

ICT Industrial can self-perform the majority of structural and mechanical field construction work including:

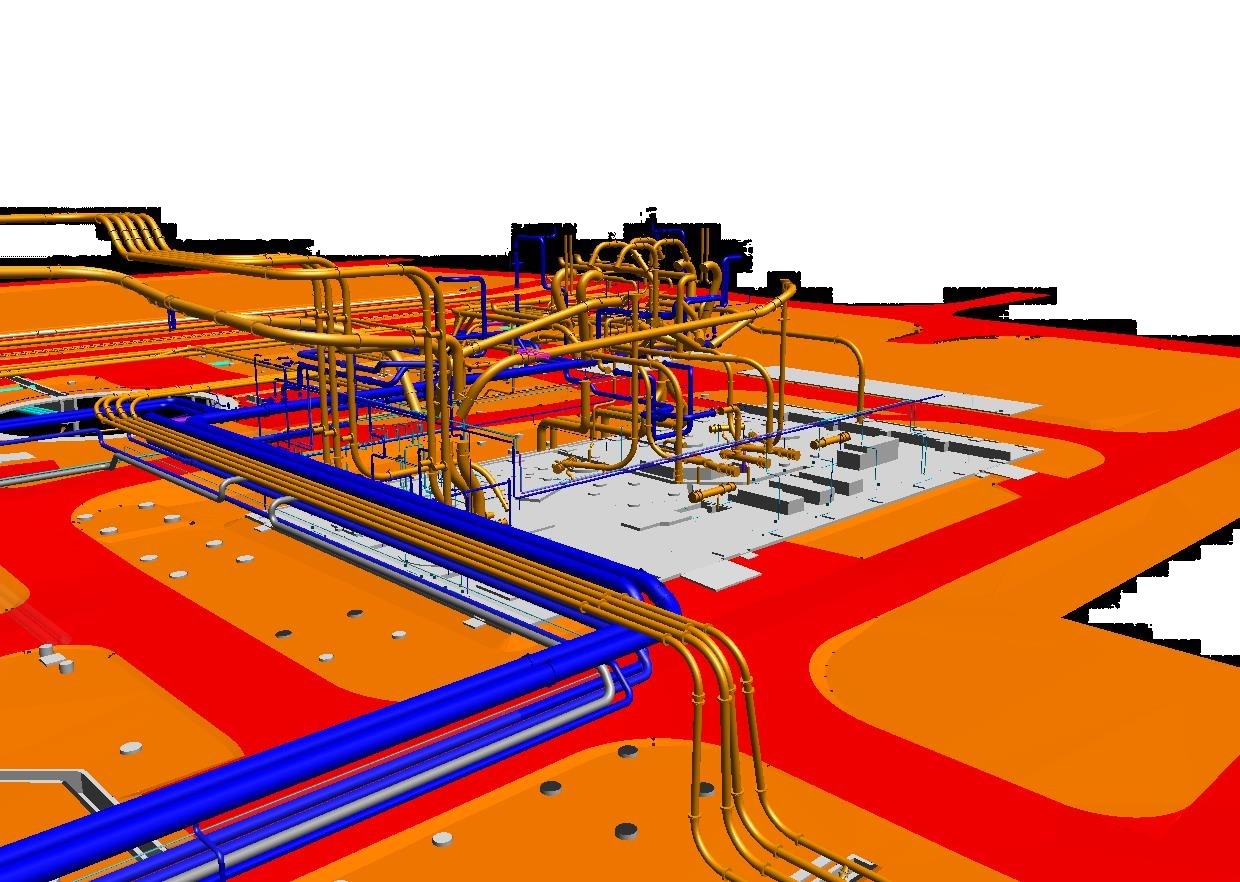

- Pipe Installation

- Steel Erection

- Equipment Installation (Static & Rotating)

- Module Installation

- Material Marshalling / Preservation

- Scaffolding

- Engineering / Consulting

- Pre-Construction / Constructability

- Maintenance

- Turnaround / Shutdowns

- Commissioning

Other disciplines of work such as pipe/steel fabrication, heavy earthworks, concrete, electrical, instrumentation, coatings, and insulation are evaluated on a project-by-project basis to determine how to maximize the value of the work.

Specialty Services

In addition to being a single service provider as a General Contractor, Contractor or Subcontractor for multiple discipline projects, ICT Industrial offers specialty Fiber Reinforced Polymer (FRP) services:

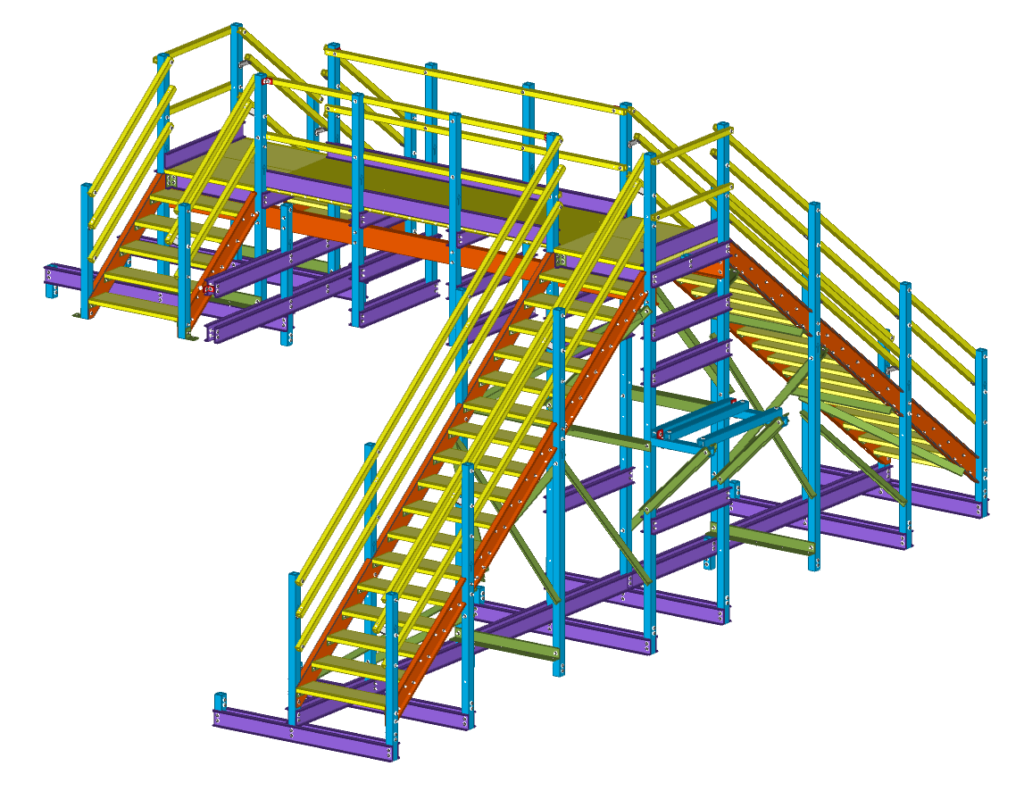

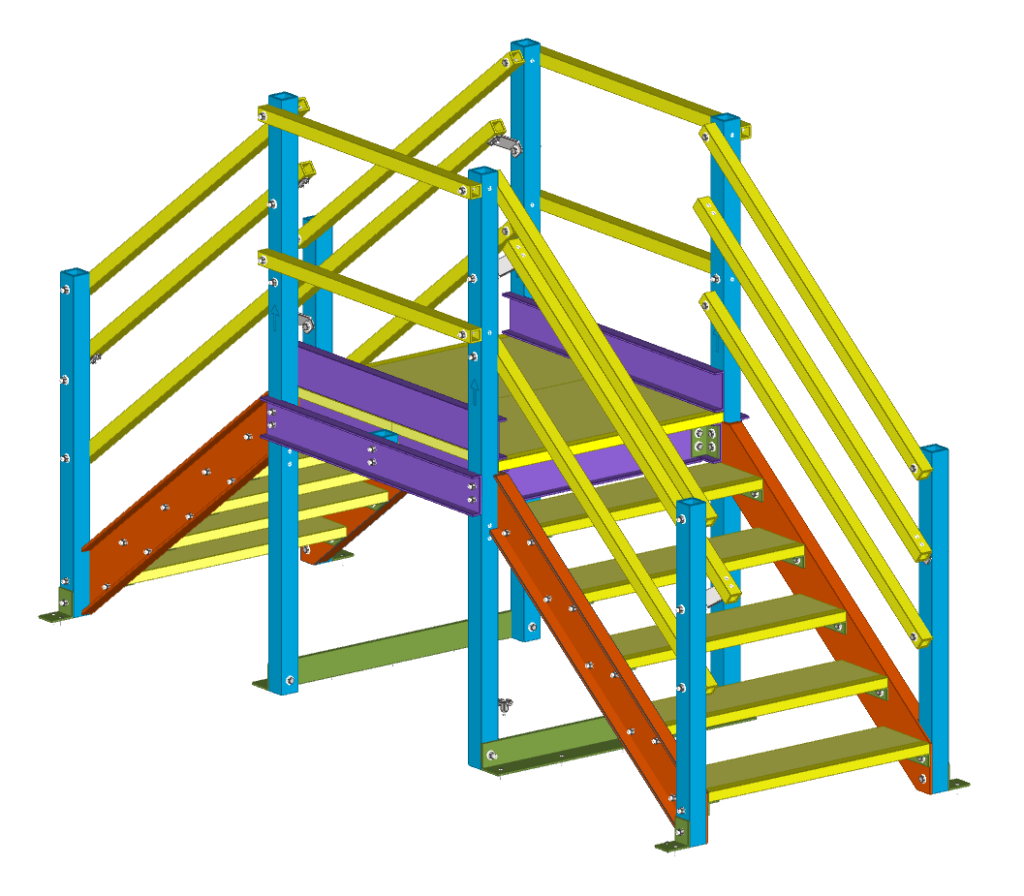

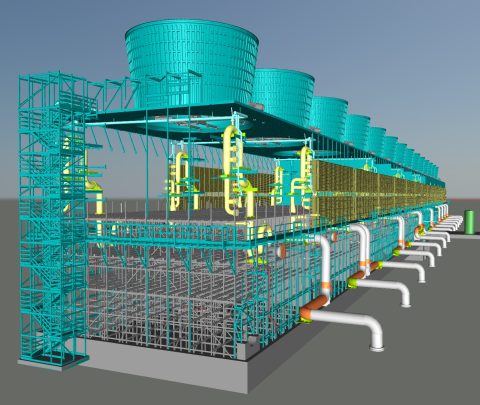

FRP Structures

ICT Industrial is expanding its services to meet the growing demand for Fiber Reinforced Polymer (FRP) solutions across a broader range of industrial applications. Offering FRP stair towers, ladders, platforms, walkways, handrail, grating, decking and support structures. ICT Industrial offers a complete FRP solution inclusive of design, pre-fabrication, supply and installation to meet our Clients needs whether they are seeking alternatives to traditional materials like steel or wood, corrosive resistance, slip-resistance, non-conducting option, light weight and/or cost-effectiveness.

Why Choose FRP for Your Industrial Secondary Structures?

- Corrosion Resistance: FRP is inherently resistant to corrosion from water, chemicals, and aggressive industrial environments.

- Lightweight: FRP is up to 75% lighter than steel, making it easier to transport, handle, and install. Eliminating or reducing the need for cranes to support installation.

- Slip-Resistant Surfaces: Available for grating and decking, FRP improves worker safety in wet or oily conditions.

- High Strength-to-Weight Ratio: Despite its light weight, FRP delivers high tensile and flexural strengths, ensuring structural integrity without the burden of excess weight or the need for extensive support systems.

- Low Maintenance: FRP eliminates the need for painting, coating, or frequent repairs, significantly reducing long-term maintenance costs.

- Fire Retardant: Our FRP products meet ASTM E84 Class A fire ratings, ensuring compliance with stringent safety standards in high-risk environments.

- Electrically Non-Conductive: FRP enhances safety in environments with electrical hazards, making it ideal for power plants and other electrically sensitive facilities.

Specialty Services

In addition to being a single service provider as a General Contractor, Contractor or Subcontractor for multiple discipline projects, ICT Industrial offers specialty Fiber Reinforced Polymer (FRP) services:

FRP Piping

In demanding industrial environments, durability, cost-efficiency, and reliability are more than just requirements – they are essentials. Fiber Reinforced Polymer (FRP) piping solutions are specifically engineered to transcend traditional materials like steel and aluminum, offering businesses a smarter, more efficient alternative. As a trusted supplier of FRP solutions, ICT Industrial provides access to a comprehensive range of products that meet or exceed stringent industry standards

Unmatched Corrosion Resistance

Corrosion can wreak havoc on traditional materials such as steel, which often require costly protective coatings or frequent maintenance to prevent rust and chemical degradation. FRP piping eliminates this concern by being inherently corrosion resistant. This is particularly critical in harsh environments where exposure to chemicals, moisture, and aggressive agents accelerates wear on traditional infrastructure.

Lightweight Yet Strong

Strength does not have to come at the cost of weight. FRP piping is significantly lighter than materials like steel, which translates to:

- Reduced installation costs: Lower reliance on heavy lifting equipment.

- Simplified field modifications: Cutting and adjustments are easier and faster.

Despite its lightweight nature, FRP is engineered for strength and rigidity, capable of withstanding high pressures, extreme temperatures, and demanding industrial loads. This unique combination of properties makes FRP piping ideal for even the most challenging applications.

Enhanced Durability and Design Flexibility

FRP piping solutions cater to a wide range of industrial needs, offering customizable diameters, wall thicknesses, and designs to handle even the most demanding requirements. Whether it is high-flow process piping, large-diameter exhaust stacks, or support systems for corrosive environments, our solutions can be customized to meet specific requirements.

In addition, ICT Industrial FRP products are engineered to conform to relevant ASTM and ISO standards, ensuring that you receive a high-performing product that complies with industry standards. This flexibility in design also allows for easy integration into both new installations and retrofit projects.